Since FY17, FDA has been conducting Foreign Supplier Verification Program (FSVP) inspections on a year-over-year increasing basis. Although the overall number of citations has dropped since FY21, more than half of the inspections continue to have findings of “objectionable conditions or practices,” with the top citation continually being the failure to develop an FSVP. In fact, in FY23 about 35% of the FSVP citations were caused by that failure.

With a focus on FY21-FY23, FDA Consumer Safety Officer Lorie Hannappel explained in a recent FSPCA webinar, FDA FSVP Update, that the numbers include both onsite and remote inspections for both human and animal food inspections, although the majority of inspections – and citations – were for human food facilities.

While FDA wants to see citation numbers decrease, the agency is continually increasing its number of FSVP inspections, with plans to conduct 2,000 inspections in FY24. Although final numbers had not been tallied for FY23 at the time of the webinar, the statistics showed that of the approximately 1,100 completed inspections, nearly 600 included citations for conditions/practices that led to the official recommendation for regulatory and/or administrative actions (OAI) or voluntary action (VAI). (TAG update: as of this writing, FDA’s Data Dashboard shows 1,652 inspections conducted in FY23, with 877 (53%) receiving OAIs/VAIs.)

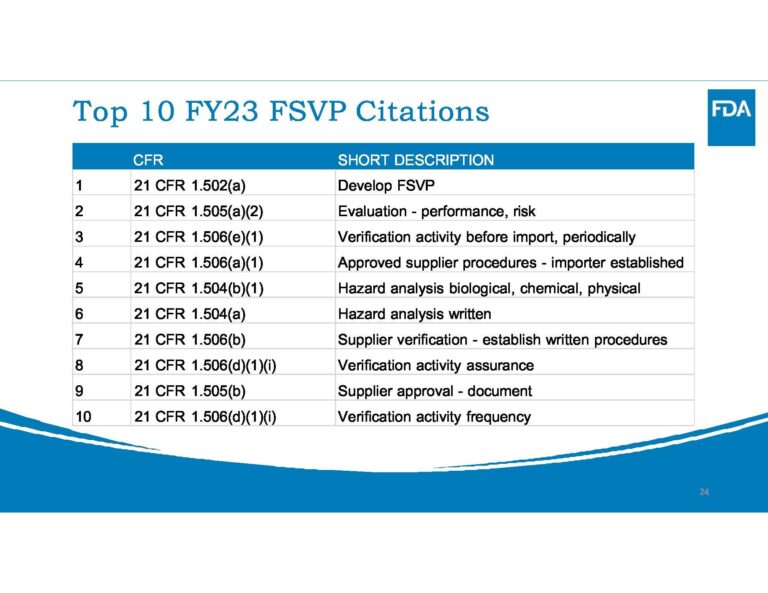

In addition to the failure to develop an FSVP, 483 citations were issued for:

- Verification: failure to conduct and document verification activity prior to and periodically after importing; no or inadequate written procedures for verification activities; failure to determine and document verification activities for adequate assurance of food safety; and/or insufficient determination and documentation of frequency of adequate verification activities

- Hazard Analysis: Lack of identification of a hazard or documentation of its analysis

- Evaluation: Lack of evaluation of foreign suppliers’ performance or risk; no documented, review and assessment of any evaluation by another entity, and/or no documented approval of a foreign supplier’s evaluation

If a 483 is issued with an FSVP OAI, and the importer fails to take corrective action for compliance, a warning letter may be issued to the importer. However, there is a major difference between warning letters for regular FDA inspections and FSVP inspections. That is that a noncomplying importer may be placed on import alert resulting in the automatic Detention Without Physical Examination (DWPE) of all future shipments until the import alert is resolved. Additionally, an FSVP import alert is not a normal import alert. For a standard import alert, FDA acceptance of a petition evidencing root cause analysis, corrective action, and verification, along with five consecutive shipments released as compliant, can get the import alert released. (For more information, see TAG’s article on Import Alert Removal.)

But, because the basis of an FSVP Import Alert is noncompliance with FSVP, the five shipment compliance is not applicable, rather the importer must submit a petition demonstrating compliance through proven corrective action. If the petition meets FDA criteria for removal, the importer will receive a letter indicating removal from DWPE. This whole process can take months, with significant financial consequences, so better to avoid it in the first place

One further area covered in the webinar was information on remote inspections, which were begun during the COVID-19 pandemic when inspectors were unable to get into facilities. FDA continues to conduct some FSVP inspections remotely but has created a secure portal to increase efficiencies, simplify communications, and address challenges of the initial remote process. If a remote inspection is to be conducted, the importer will be given a link to the portal through which requested records can be uploaded. The portal enables large records to be submitted, allows for the control of types of records and prevention of additional uploads after inspection close-out, and provides a site for importers to check inspection status. While on-site inspections are still preferred to better enable facility understanding and accurate verification of activities, remote inspections provide an efficient way to review records without excess travel.

The FSVP rule has been in effect since January 2016, with inspections conducted since FDA FY17. Yet, six years later, more than half of the FDA inspections are including citations for a complete lack of development of the FSVP. This may be because producers are not requiring them of their importers, importers don’t understand the need or means of development, businesses are simply not taking the time to do them, or a myriad of other excuses or explanations. But regardless of the reason, your lack of a complete and adequate FSVP could cause your imported products to be detained at the border – with you struggling to quickly develop an acceptable FSVP to enable the imports to come through.

Don’t wait until your imports are caught at the border, our FSVP experts can help develop your FSVPs or assess existing programs for FDA compliance. Give us a call!