As consultants, the TAG Team counsels food and beverage companies on a daily basis on issues and concerns in their establishments or those of their suppliers. Many of the concerns are fairly common across establishments, and in some cases, they arise out of misunderstandings related to the science of microorganisms, the need to control their growth, and applicable risk management strategies – and regulations.

While quality assurance and food safety teams learned the basics in their university years, that could have been a while back for many. Additionally, it’s not always simple to apply the basics of the science to each facility’s operations and production. So what’s the answer? Essentially the goal is to leverage data to both understand the processes and determine and apply the ideal risk management strategy.

One such common misunderstanding is that of the development of sporeforming bacteria (e.g., Bacillus and Clostridium species) when cooling is not effectively managed. As defined in Science Direct, “the spores of these species are dormant bodies that carry all the genetic material as is found in the vegetative form, but do not have an active metabolism.” However, when environmental conditions become favorable, the spores can germinate to produce a toxin. If you can prevent that growth, you can prevent the formation of the toxin – and the food contamination and possible illnesses and/or a recall that could go along with it.

To provide more detail, let’s look at the following question: “I hold batter at about 65°F for no more than 72 hours, which I then cook, and freeze the product. Why is FDA concerned?”

Improper/slow cooling is one of the most common factors contributing to foodborne-disease outbreaks according to CDC reports. Because pathogens grow fastest between temperatures of 70°F – 135°F, foods that require time/temperature control for safety (TCS foods) must pass through this “danger zone” as quickly as possible, within very specific maximum timeframes:

- Cool TCS food from 135°F to 41°F or lower in 6 hours

- Step 1: 135°F to 70°F within 2 hours

- Step 2: 70°F to 41°F within 4 hours

- If food has not reached 70°F in 2 hours, it must be thrown out or reheated to 165°F and used for immediate service, or cooled correctly

However, there is a great deal more to food safety than just cooling time (how simple life would be if that were all there was to it!). But it is because there are so many more potential hazards in need of control that we have HACCP, FSMA regulations, and food safety programs in general. Because you can only control what you can understand, the basis of all food safety is understanding the hazards that exist in the ingredients and production process, then controlling them effectively.

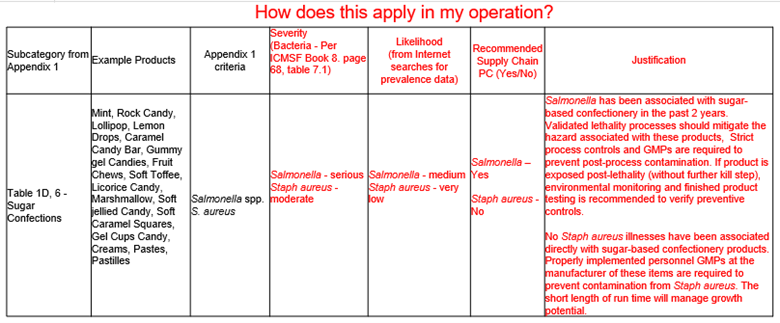

Thus, a key aspect of food safety is identifying the hazards then applying applicable criteria to the food safety plan to address them. Appendix 1 (Potential Hazards for Foods and Processes) of FDA’s Preventive Controls Guidance has a great deal of information, but at 233 pages, all aspects of the document may not be applicable to all foods. But because they are potential hazards that need to be controlled, an FDA inspector could ask you about your control of any of them. So, it is critical to be prepared, understand the applicable and nonapplicable hazards for your products and processes, apply the criteria to your own food safety plan, then be able to justify your decisions as why a control is applied – or not (as shown in the example below).

Once your hazard assessment is conducted and valid controls implemented, it is important to verify their effectiveness. This may be through methods such as microbiological tests, ATP monitoring, rapid allergen screening, record reviews, or even a visual evaluation of cleanliness – which if not done properly, can be the key cause of contamination. In fact, design/maintenance of equipment/utensils and sanitary operations were among the top five reasons for FDA 483 citations in FY21. Ensuring your facility is confidently executing the best strategies is critical.

So, once you’ve assessed the hazards, ascertained relevant risk, and implemented controls, how do you ensure that you continue to be managing the “right” risks? There are many food safety hazards which can newly emerge and may be poorly understood. However, that does not give a food establishment a pass, should a novel hazard create a risk. It remains important to thoroughly understand your product and processes, stay alert for new hazards, then consider when it’s time to revise the hazard analysis and put new controls in place to reduce risk and focus your efforts.

The takeaway from all this? Optimally applying appropriate risk management practices will enable you to effectively manage relevant risks.